Software control for AGRETO drive-over-scale

EUR

1212.00

€ 1.212,00

incl. 20 % VAT

Shipping costs:

|

Germany

Austria

other countries

|

free

free

|

delivery time 1-3 days

Art. No. AW07

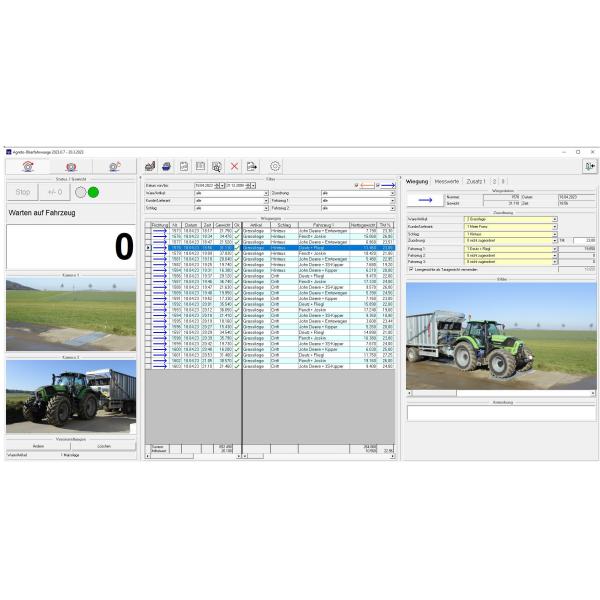

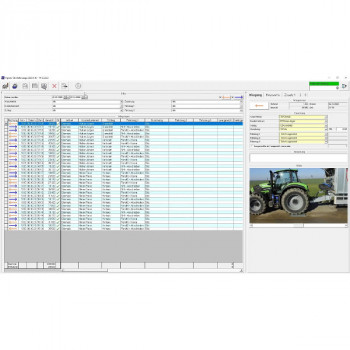

USB-Box and PC-Software to operate the AGRETO drive-over-scale •

Data management for master data and weighings • Creating weighing notes and lists • Weighing with wireless remote control and image processing

Product description

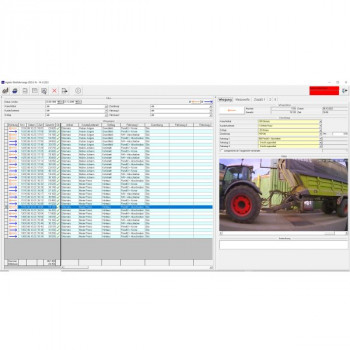

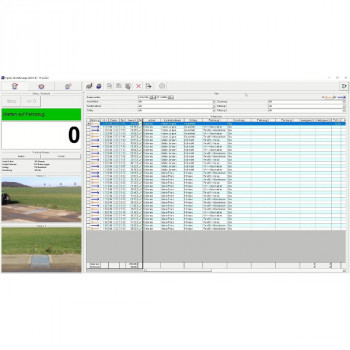

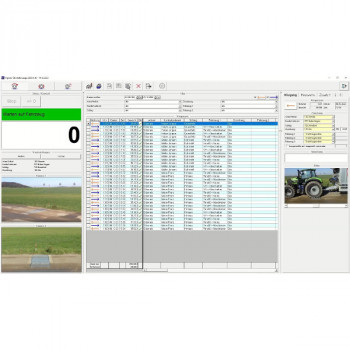

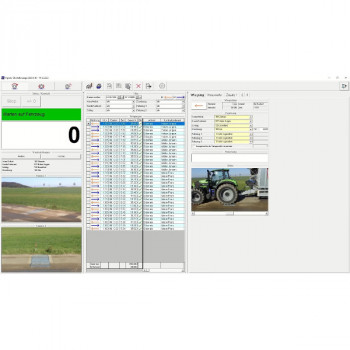

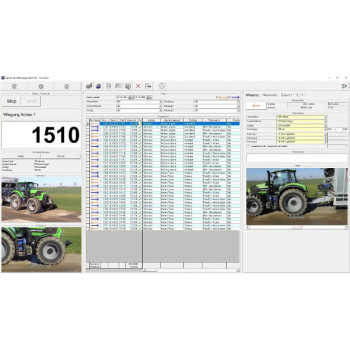

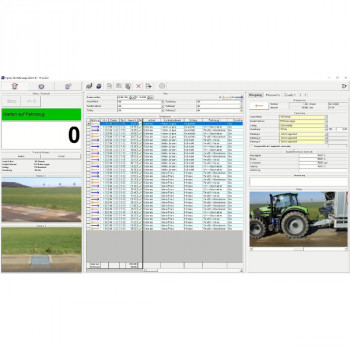

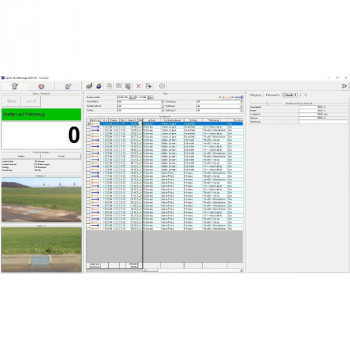

Weighing data management on PC

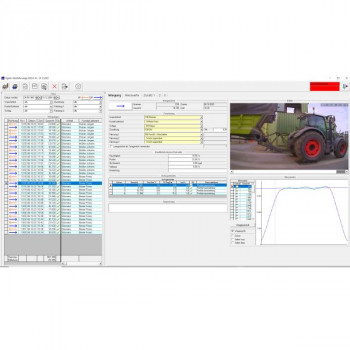

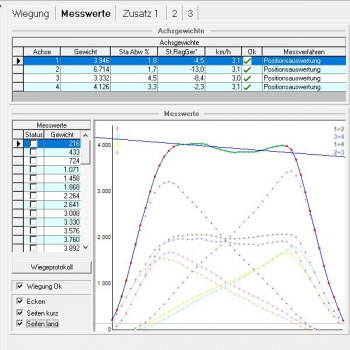

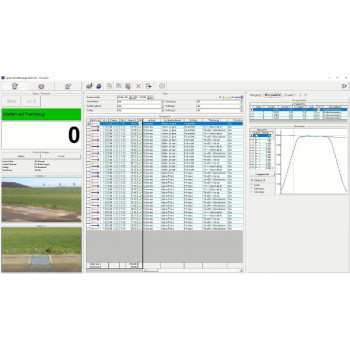

The weighings are automatically recorded in the PC software with all the details. Weighing curves of each axle are illustrateted and also the quality of the weighing is calculated and displayed.

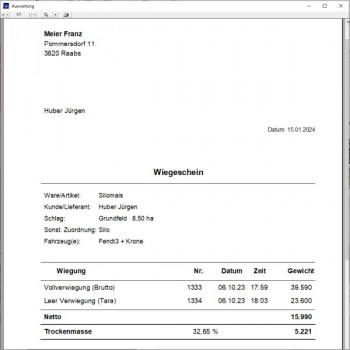

Creating weighing notes and lists

The software creates the necessary weighing notes, evaluation and billing lists. You can use standard or individual layouts which you can adjust with the included designer tool.

Master Data Management

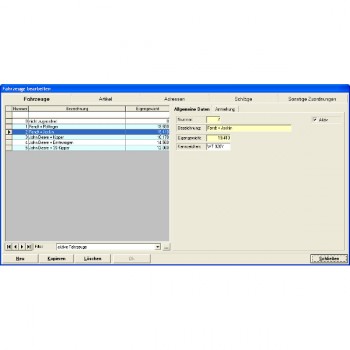

In the software the products, customers, suppliers, fields, vehicles and other assignments are maintained. The informations can be automatically or manually assigned to the weighings. This can be done in advance or afterwards.

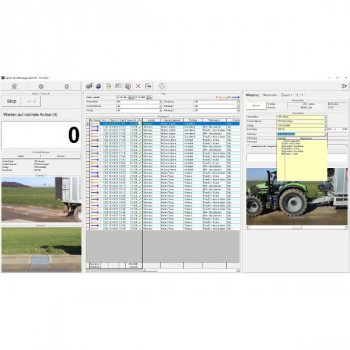

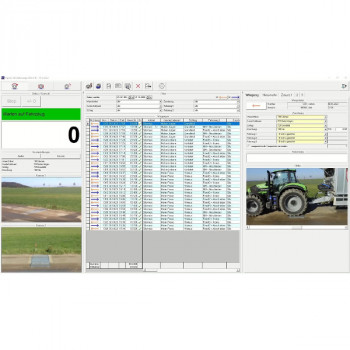

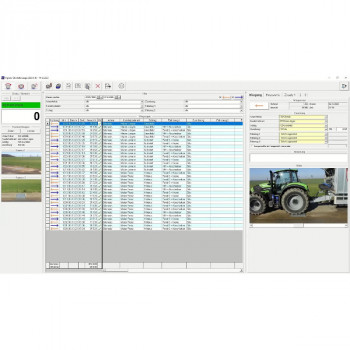

Weighing with wireless remote control

The driver or the vehicle logs on at the scale with a wireless transmitter. The software recognizes the registration, releases the scale and stores automatically all the information associated to the wireless transmitter to the current weighing. This can be the vehicle data including tare weight or other information such as supplier, products, fields etc.

Image Processing

If a camera is mounted at the scale, the software automatically creates images from each vehicle. With this photographic evidence the user can identify the vehicles in retrospect.

Automatic determining of the transport quantities

Through the automatic weighing process and the direction detection transported quantities can be determined fully automatically. You can drive simply over the scale with all vehicles. With load in one direction, qithout load in the other direction. From the difference the softwrae is calculating the transported amount. With this functionality the scale is ideal for large quantity of documentation on farms, biogas plants and heating plants.

NEW from version 2023

The software was revised in 2023, the following functionalities are new:

• New user interface with freely customizable elements

• Free definition and design of data entry for up to 30 additional pieces of information for each weighing

• Weighing without light barriers - position detection via the software replaces the light barriers

• Simultaneous weighing and editing of weighings without restrictions

Technical data

Delivery contents:

• 1 Software AGRETO drive-over-scale on USB-Stick

• 1 USB-Box

• 1 USB cable

• 1 Power supply

• 1 User manual

• 1 USB-Box

• 1 USB cable

• 1 Power supply

• 1 User manual

PC-Requirements:

• Pentium III or higher

• Windows 10 / 11

• 1 free USB-Port

• additional USB-Ports for accesories

• Windows 10 / 11

• 1 free USB-Port

• additional USB-Ports for accesories

AGRETO drive-over-scale weighing software:

• Modern Windows user interface with individual adjustment of the elements

• Management and control of the scale and the accessories used

• Master data management for addresses, articles, vehicles with curb weights, fields, assignments

• Weighing with radio remote control with assignment of presets

• Weight display and status displays

• Recording of weighings with date, time, direction of travel, driving speeds and all weights

• 3 weighing modes: dynamic, static and manual weighing

• List display of weighings with filter and sorting functions

• Quality control of the weighings via driving speed and statistical functions

• Graphical visualisation of the weighing curve of each axis with all measuring points

• Display of the live images from the cameras and the images stored for the weighings

• Manage presets for weighings

• Subsequent editing of weighings

• Dry matter management

• Creating and printing weighing notes and weighing lists

• Integrated list designer for individual evaluations

• Data export to Excel or other formats

• Data backup and data recovery

• Remote maintenance tool for support via the Internet

• Management and control of the scale and the accessories used

• Master data management for addresses, articles, vehicles with curb weights, fields, assignments

• Weighing with radio remote control with assignment of presets

• Weight display and status displays

• Recording of weighings with date, time, direction of travel, driving speeds and all weights

• 3 weighing modes: dynamic, static and manual weighing

• List display of weighings with filter and sorting functions

• Quality control of the weighings via driving speed and statistical functions

• Graphical visualisation of the weighing curve of each axis with all measuring points

• Display of the live images from the cameras and the images stored for the weighings

• Manage presets for weighings

• Subsequent editing of weighings

• Dry matter management

• Creating and printing weighing notes and weighing lists

• Integrated list designer for individual evaluations

• Data export to Excel or other formats

• Data backup and data recovery

• Remote maintenance tool for support via the Internet

FAQ

What are the advantages of using a PC for the scale instead of a conventional weighing terminal?

• The weighings are clearly displayed with all data on the PC screen and can be supplemented with a lot of additional information (article, customer, supplier, field, etc.).

• All details of the weighing down to the individual measuring points on each corner of the scale are recorded and can be analyzed.

• The software can be used to create individual weighing slips, evaluation and billing lists.

• Extensions or accessories such as radio remote control and image processing are possible.

• The scale data can easily be integrated into an automated security concept.

• PCs are widely used devices and can be easily replaced in the event of damage without long scale downtime.

• All details of the weighing down to the individual measuring points on each corner of the scale are recorded and can be analyzed.

• The software can be used to create individual weighing slips, evaluation and billing lists.

• Extensions or accessories such as radio remote control and image processing are possible.

• The scale data can easily be integrated into an automated security concept.

• PCs are widely used devices and can be easily replaced in the event of damage without long scale downtime.

How about PC requirements?

You can use any regular PC or notebook with a Windows operating system (Windows 10 or 11). The system has to be stable and reliable. The scale requires a USB port. Depending on what accessory is used, more USB or serial ports might be required.

How far can the PC be removed from the scale?

The serial cable connection from scale to PC can measure up to 100 m. The cable is delivered in the required length. From a practical point of view, however, it's more advantageous when the PC is situated near the scale, especially when weighings require manual input or the printing of weight notes.

Can tare weights of vehicles be stored in the software?

Yes, all vehicles/trailers and their tare weights can be registered in the software's master data section. These tare weights can be allocated to weighings at a later time. This allocation can be done manually, with the help of images of the vehicles (via the image processing accessory) or automatically by letting the vehicles register through a wireless transmitter (via the remote control accessory).

Any more questions?

Please call us: +43 2846 620

Downloads

Driver:

High Resolution Pictures:

0 Review(s)

No reviews available