Weighing modules for silos 4 x 2 t with XK4

EUR

888.00

€ 888,00

incl. 20 % VAT

Shipping costs:

|

Germany

Austria

other countries

|

free

free

|

delivery time 1-3 days

Art. No. AGW082T4XK4

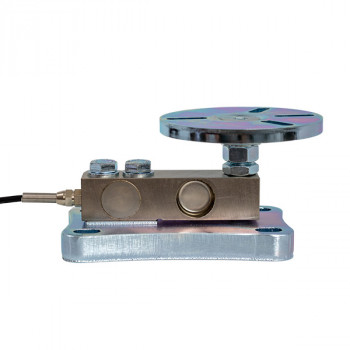

Weighing modules for silos, tanks and containers • Shear beam load cells with high accuracy • Dust and waterproof according to protection class IP68 • Robust mounting plate for fixing on the floor • Movable load introduction • Consisting of 4 modules with a nominal load of 2,000 kg each for weighing applications up to approx. 6 t • Standard XK4 weighing indicator with 1 kg resolution

Product description

Affordable weighing modules - simple installation

With this set, professional weighing technology can be quickly and easily mounted under the feet of a silo or under other containers and structures.

Flexible load introductionc

The special design of the load introduction with the mounting plate, which can be moved in all directions, compensates for tensions and inclinations in all directions.

High Accuracy

The weighing modules use high-resolution shear load cells, as are also used in calibrated scales. These have a better resolution than the round compression load cells usually used for silo scales.

Inexpensive standard weighing indicator

The XK4 weighing indicator is an inexpensive universal indicator for standard weighing processes for silos and containers.

Ready for immediate use - no specialist knowledge required

The weighing technology set is completely wired up and put into operation on a trial basis. The weighing display is adjusted with a calibration weight and the necessary parameters are set. You can put the scale into operation immediately after installation.

Technical data

Built-in module:

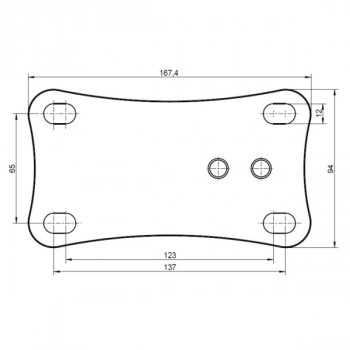

• Base plate 167 x 94 x 20 mm (LxWxH) with slotted holes 12 mm for fixing to the floor, hole spacing 123 to 137 x 65 mm

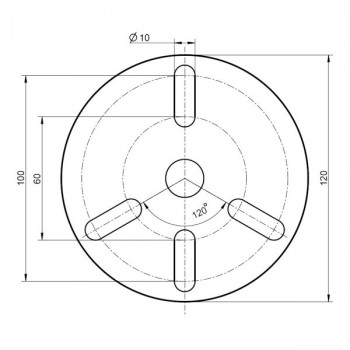

• Mounting plate 120 x 10 mm (DxH) with slotted holes 10 mm for attaching the superstructure

• Movable load introduction

• All steel parts galvanized

• Total height 95 to 110 mm

• Weight incl. load cell 4.0 kg

• Mounting plate 120 x 10 mm (DxH) with slotted holes 10 mm for attaching the superstructure

• Movable load introduction

• All steel parts galvanized

• Total height 95 to 110 mm

• Weight incl. load cell 4.0 kg

Load cell:

• high-resolution shear force load cell, 3 mV/V, 350 Ohm

• Robust design made of nickel-plated tool steel

• Nominal load per load cell 2,000 kg

• safe overload 120 %, breaking load 150 %

• accuracy +/-0.02 %

• cable length 4 m

• Dust and waterproof according to protection class IP68

• Operating temperature -35 to +65 °C

• Temperature compensated -10 to +40 °C

• Robust design made of nickel-plated tool steel

• Nominal load per load cell 2,000 kg

• safe overload 120 %, breaking load 150 %

• accuracy +/-0.02 %

• cable length 4 m

• Dust and waterproof according to protection class IP68

• Operating temperature -35 to +65 °C

• Temperature compensated -10 to +40 °C

Connection box:

• Dust and waterproof connection box according to protection class IP67

• Spring terminals for load cells and weighing signal cables

• Cable outlets with cable glands

• Spring terminals for load cells and weighing signal cables

• Cable outlets with cable glands

Agris XK4 weighing indicator:

• Display unit in plastic casing

• Stainless steel bracket for mounting to wall or table

• Adapter for stand mounting

• Dimensions including mounting bracket 280 x 160 x 95 mm (WxHxD)

• Protection class IP63

• Connection to the load cells via waterproof screw plug

• 6-digit LED display with 25 mm high, bright red digits

• Automatic auto-zero when switching on or manual zero

• Zero point stabilisation

• Taring and summing function

• Energy saving mode to preserve the battery

• Power supply through external 230 V power adapter or built-in battery

• Stainless steel bracket for mounting to wall or table

• Adapter for stand mounting

• Dimensions including mounting bracket 280 x 160 x 95 mm (WxHxD)

• Protection class IP63

• Connection to the load cells via waterproof screw plug

• 6-digit LED display with 25 mm high, bright red digits

• Automatic auto-zero when switching on or manual zero

• Zero point stabilisation

• Taring and summing function

• Energy saving mode to preserve the battery

• Power supply through external 230 V power adapter or built-in battery

Scope of delivery

Scope of delivery:

• 4 weighing modules with built-in load cells

• 1 connection box

• 6 m connection cable to the weighing indicator

• 1 XK4 weighing indicator

• 1 User manual

• 1 connection box

• 6 m connection cable to the weighing indicator

• 1 XK4 weighing indicator

• 1 User manual

FAQ

For which weighing applications can the weighing modules be used?

The weighing modules can be used for any weighing construction. They are ideal for mounting on silo bases or underneath containers and other structures.

Why are built-in modules useful?

When using shear force load cells, the horizontal offset of the applied force creates the bending moment required for the measurement in the load cell. However, this bending moment must be neutralized by the structure to which the load cell is attached. This means that the area where the load cell is attached must be dimensioned so sturdily that it can safely absorb this bending moment and does not bend or strain. This is not normally guaranteed with the base of a silo, which is why the weighing module takes on this task. The installation module can also be used to secure the silo to the floor and prevent it from tipping over.

How strong is the lift-off protection dimensioned?

With Agris weighing modules, the lift-off protection is provided by the load cell and load application itself, and is limited to the maximum load of the load cell. The module is therefore not suitable for high silos in outdoor areas where strong wind forces are to be expected.

How much higher does the weighing module make the silo?

Due to the space-saving design of the load introduction, the overall height of the module is only between 95 and 110 mm, depending on the setting of the fastening parts. The overall construction is higher by this amount.

How are the weighing modules attached to a silo?

In a silo, a weighing module is mounted under each base. The base plate, with which the silo foot previously stands on the ground, is now placed on the round disk of the weighing module and screwed in place. Slotted holes are provided for this purpose. If it is not possible to attach the foot to the plate, an intermediate construction is required.

Do the mounting plates fit the CSI1 grain silo?

Yes, the mounting plates can also be used directly for the CSI1 grain silo. However, there are plates specially adapted for the CSI1 silo, which we supply when you purchase the scales as an accessory for the silo.

Does the module have to be fixed to the floor?

For safety reasons alone, silos and containers that are at risk of falling over or being knocked over should be properly anchored to the floor. If the load on the weighing modules exceeds 1,000 kg per corner, they must be anchored to the floor to prevent deformation.

How exactly level and even must the floor be?

The Agris weighing modules have a load introduction that can compensate for slight lateral inclinations without compromising weighing accuracy. So if the floor is inclined by a few degrees, it can still be used, the module is then slightly inclined and the load introduction at the top compensates for this inclination. In any case, the floor must be load-bearing and must not give way under load.

How exactly horizontal must the structure be?

If the existing contact surface of a silo foot is slightly inclined, the movable load introduction of the weighing module can compensate for this inclination up to 3 degrees without restriction. However, any inclination of the module itself (in the opposite direction) must also be taken into account for these 3 degrees.

Can the height of the module vary to compensate for height differences?

Yes, but only between 95 and 110 mm. If the difference is greater, suitable plates must be positioned under the module or between the module and the superstructure.

How large can the distance between the weighing modules be?

The distance between the weighing modules is limited by the cable length of 4.5 m from the module to the collection box.

Can the cable from the connection box be extended?

Yes, it is best to order the cable in the desired length right away.

How accurately do the load cells weigh?

The load cells are high-resolution shear force load cells with an accuracy of +/- 0.02 %.

Are the load cells calibratable?

Not in the standard version, if you require a calibrated scale, please contact us.

Any more questions?

Please call us: +43 2846 620.

Downloads

Dokumente:

Hochauflösende Bilder:

0 Review(s)

No reviews available