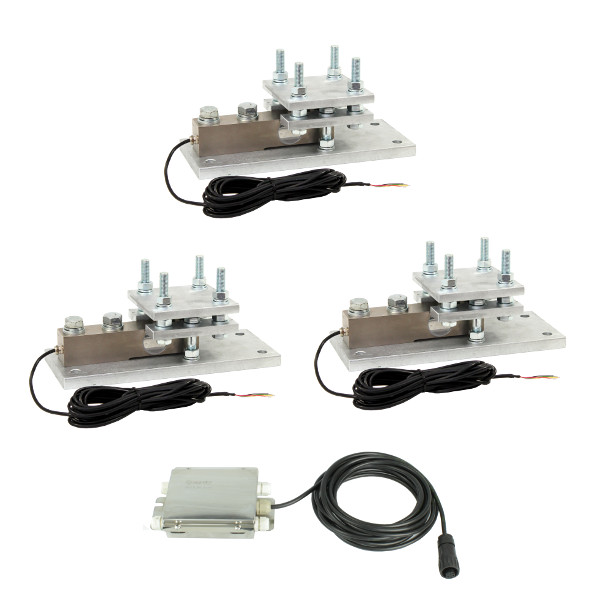

AGRETO heavy duty scales weighing module 3 x 5 t

Art. No. AGW0705X3

Easy to install weighing modules for silos, containers or machines in indoor and outdoor settings • Reliable lift-off protection (in case of wind pressure, etc.) • Different versions 5 t per module • High weighing accuracy

Product description

Versatile usable for silos in outdoor area up to 7.5 tonnes toal weight

A scale for silos, feed mixers, dosage devices, machines, tanks, containers and other vessels. Indoor and outdoor operation, absolutely dust- and waterproof according to protection class IP68.

Robust scale with lift-off protection

Reliable lift-off protection and secure absorption of lateral forces, also under high wind pressure in outdoor settings. The floating construction of lift-off protection elements compensates tensions and material expansion. There's no transfer of tension and torque to the load cells.

Easy and quick installation without special tools

The modules are delivered in assembled state, you only have to mount the upper construction on the head plates. The fastening downwards is the last working step.

Loadcell replacement without disassembly

If a loadcell has to be replaced, the lift-off protection is used to hold the construction and the loadcell is simply pulled out.

High accuracy

Load cell accuracy is +/- 0.02%. Weighing indicator resolution is set at 10,000 parts.

Can be combined with every AGRETO weighing indicator

The weighing system (scale and weighing indicator) is calibrated in the factory and is thus ready for operation.

Technical data

Delivery contents:

• 3 or 4 heavy duty installation modules with built-in load cells

• 1 connector box

• 10 m weighing signal cable from connector box to weighing indicator

• User manual

• 1 connector box

• 10 m weighing signal cable from connector box to weighing indicator

• User manual

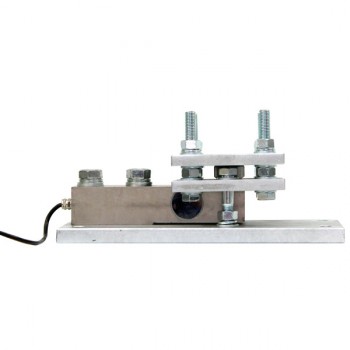

Heavy duty installation module:

• Base plate 300 x 150 x 25 mm (LxWxH) for load cell mounting and holes for ground fastening

• Top plate 150 x 150 x 20 mm with M16 screws for construction mounting

• Flexible load introduction from top plate to load cell

• 2 lift-off protection plates per element, attached with one M16 screw

• All steel parts are galvanized

• Total height: 124 mm

• Top plate 150 x 150 x 20 mm with M16 screws for construction mounting

• Flexible load introduction from top plate to load cell

• 2 lift-off protection plates per element, attached with one M16 screw

• All steel parts are galvanized

• Total height: 124 mm

Load cell:

• High-resolution shear force load cells made from tool steel

• 5 t nominal load, 150% secure overload (7.5 t), 300% breaking load (15 t)

• +/- 0.02% accuracy

• 2 mV/V characteristic value

• 5-12 Volt power supply, 350 Ohm resistance

• Waterproof according to protection class IP68

• 2 x M20 mounting screws

• Dimensions: 48 x 52 x 235 mm

• Operating temperature: -35 to +65 °C

• Temperature compensated: -10 to +40 °C

• 5 t nominal load, 150% secure overload (7.5 t), 300% breaking load (15 t)

• +/- 0.02% accuracy

• 2 mV/V characteristic value

• 5-12 Volt power supply, 350 Ohm resistance

• Waterproof according to protection class IP68

• 2 x M20 mounting screws

• Dimensions: 48 x 52 x 235 mm

• Operating temperature: -35 to +65 °C

• Temperature compensated: -10 to +40 °C

Connector box:

• Waterproof connector box

• Connecting terminals for 4 weighing cells and weighing signal cable

• Potentiometer for corner adjustment of load cells

• Cable outlets with cable screw connections

• Connecting terminals for 4 weighing cells and weighing signal cable

• Potentiometer for corner adjustment of load cells

• Cable outlets with cable screw connections

Weighing signal cable:

• 4-pin cable 4 x 0.5 mm2

• 7.6 mm outer diameter

• Special coating

• UV-resistant

• Small bending radius

• Treadable

• 7.6 mm outer diameter

• Special coating

• UV-resistant

• Small bending radius

• Treadable

FAQ

For which weighing procedures can the AGRETO heavy duty modules be used?

The AGRETO heavy duty modules are used for weighing silos, containers, tanks, feeding mixers and other constructions, indoors as well as outdoors.

How are AGRETO heavy duty modules installed?

The modules are attached to the ground through the base plate, which has a hole in every corner. Normally anchor bolts or dowels are used for concrete floors. The construction is then screwed to the modules' top plate. Extra holes or slits might have to be made, in some cases an extra plate is necessary.

How do AGRETO weighing modules get connected?

Load cell cables go to the connector box and get connected there. The connector box is mounted to the construction in an appropriate, protected spot. The weighing signal cable runs from the connector box to the weighing indicator.

How far apart from each other can the weighing modules be?

Standard load cell cables are 6 m long. Depending on the position of the connector box, the maximum diagonal distance between modules could in theory be 12 m. However, because the connector box won't be positioned in the middle of the scale and the cables run along the sides of the construction, the distance will be smaller. Load cells with longer cables can be supplied on request, but their use is not recommended.

Can the weighing signal cable from connector box to weighing indicator be extended?

Standard cable length is 10 m. It can be extended up to 50 m.

Why do scales for silos have to be so large?

Silos in outdoor settings are exposed to wind pressure. If the wind is strong enough to raise the silo on one side, the scale's lift-off protection must make sure that the silo stays in place and doesn't tip over. At the same time the other side of the scale has to carry the silo's full weight, sometimes even more during gales. The AGRETO heavy duty modules are designed for maximum security. Lift-off protection reliability is one of the most important criteria for silo weighing systems and other outdoor constructions that are susceptible to wind.

How does the AGRETO heavy duty modules' lift-off protection work?

Every weighing module has a lift-off protection plate to both sides of the load cell, that is screwed at the corner to the top plate. Every lift-off protection plate is also fixed down with a screw that isn't completely tightened. The screw head is positioned between top plate and lift-off protection plate, without touching them. The screws are screwed into the base plate and fixed with a lock nut. This ensures that the screws will not transfer any load and affect the weighing process.

Does lift-off protection need to be set or adjusted?

Lift-off protection is set correctly in the factory. If after installation the base plate and top plate aren't parallel, the lift-off protection screws should be checked, and possibly adjusted. The screws have to be set in such a way that the screw head doesn't touch the top plate above it, or to the lift-off protection plates below. Loosen the lock nut for the adjustment, and then tighten it when done.

How is lateral stability ensured?

The AGRETO weighing modules allow for a certain amount of lateral movement to compensate tension in the construction or absorb material expansion. This range of movement is limited by the diameter of the holes in the lift-off protection plates. The load transfer from top plate to load cell takes place through a flexible load introduction foot that absorbs these lateral movements and channels the force to the middle of the load cell. This special construction for load introduction with different radii causes restoring forces that always bring the system back in the center position, so that weighing results aren't affected by friction in the drilled holes.

Can a mounted load cell be replaced?

Yes, if a load cell needs replacement, this can be done without having to disassemble the entire module, as the load is carried by the lift-off protection screws.

How accurate are the AGRETO heavy duty modules?

The AGRETO heavy duty modules contain high resolution shear force load cells with an accuracy of +/- 0.02%. The weighing indicator's resolution is pre-set to 10,000 parts.

Are the AGRETO heavy duty modules calibratable?

The standard version isn't calibrated, but a version with calibratable load cells is available on request.

How many modules can be connected to one scale?

The amount of modules is limited only by the weighing indicator that supplies power to the load cells. There are weighing indicators that can manage 8 or even 16 modules. In practice, just one weighing indicator with 4 modules is used per silo or unit.

Which weighing indicators are suited for the AGRETO heavy duty modules?

Every AGRETO weighing indicator and also a lot of weighing indicators from other manufacturers. Depending on requirements, weighing indicators with special functionality can be used as well (such as alarm function, switching function, dosing function, analogue output, control interfaces, etc.)

Any more questions?

Please call us: +43 2846 620

Downloads

Documents:

High Resolution Pictures:

Other Languages:

0 Review(s)

No reviews available